Six-month internship (July-December 2019) at battery-electric aircraft company in Santa Clara, CA.

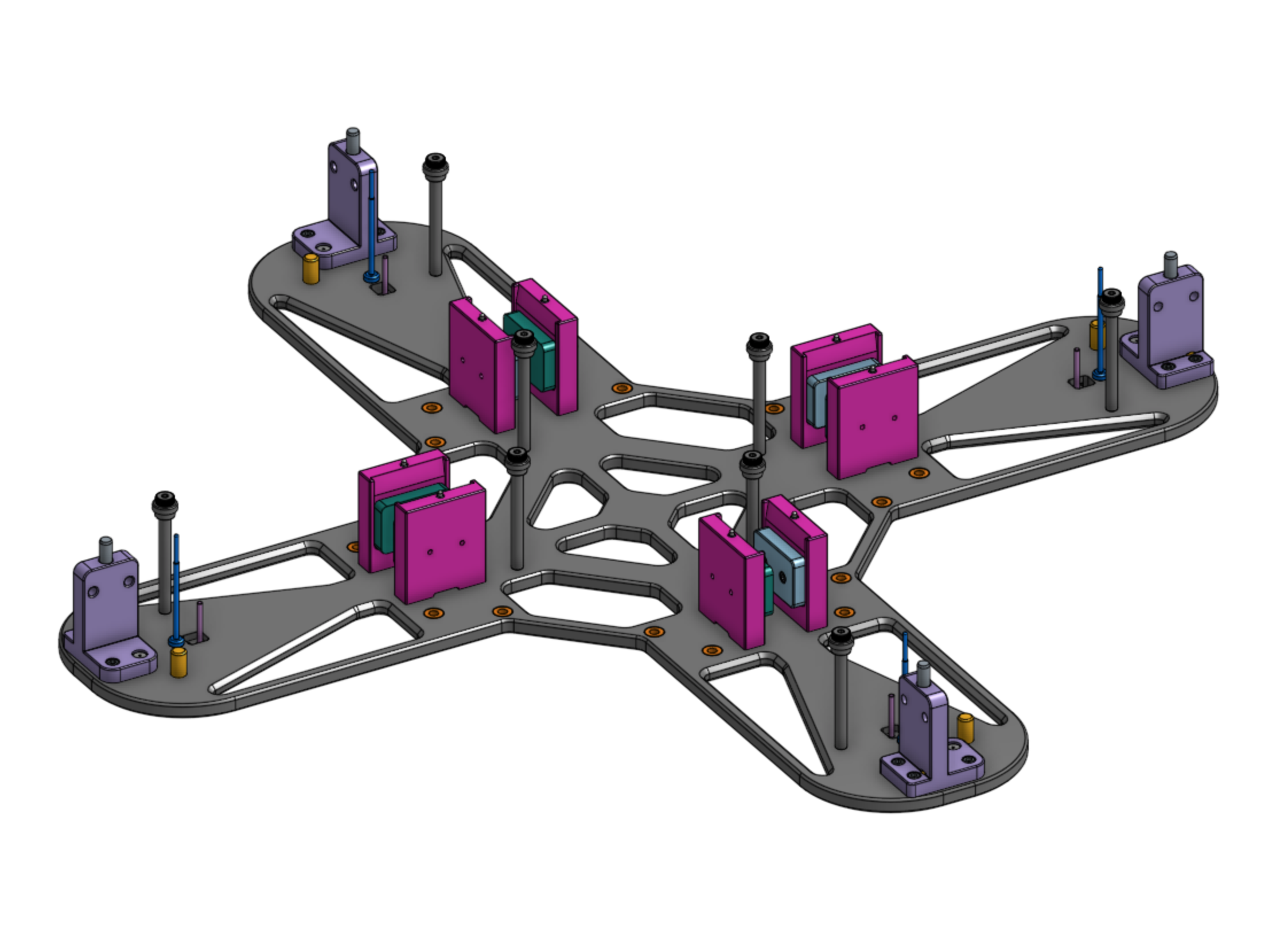

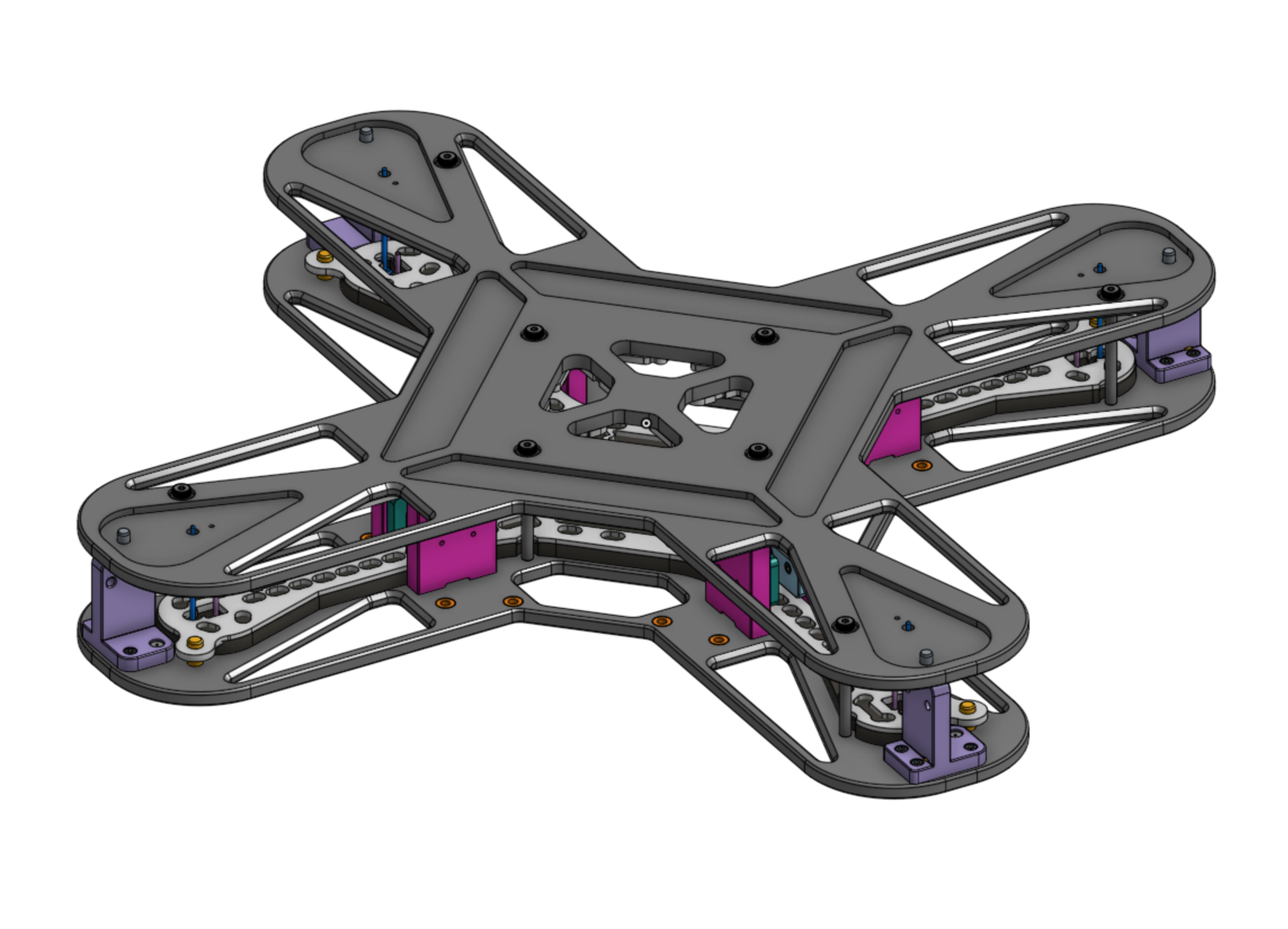

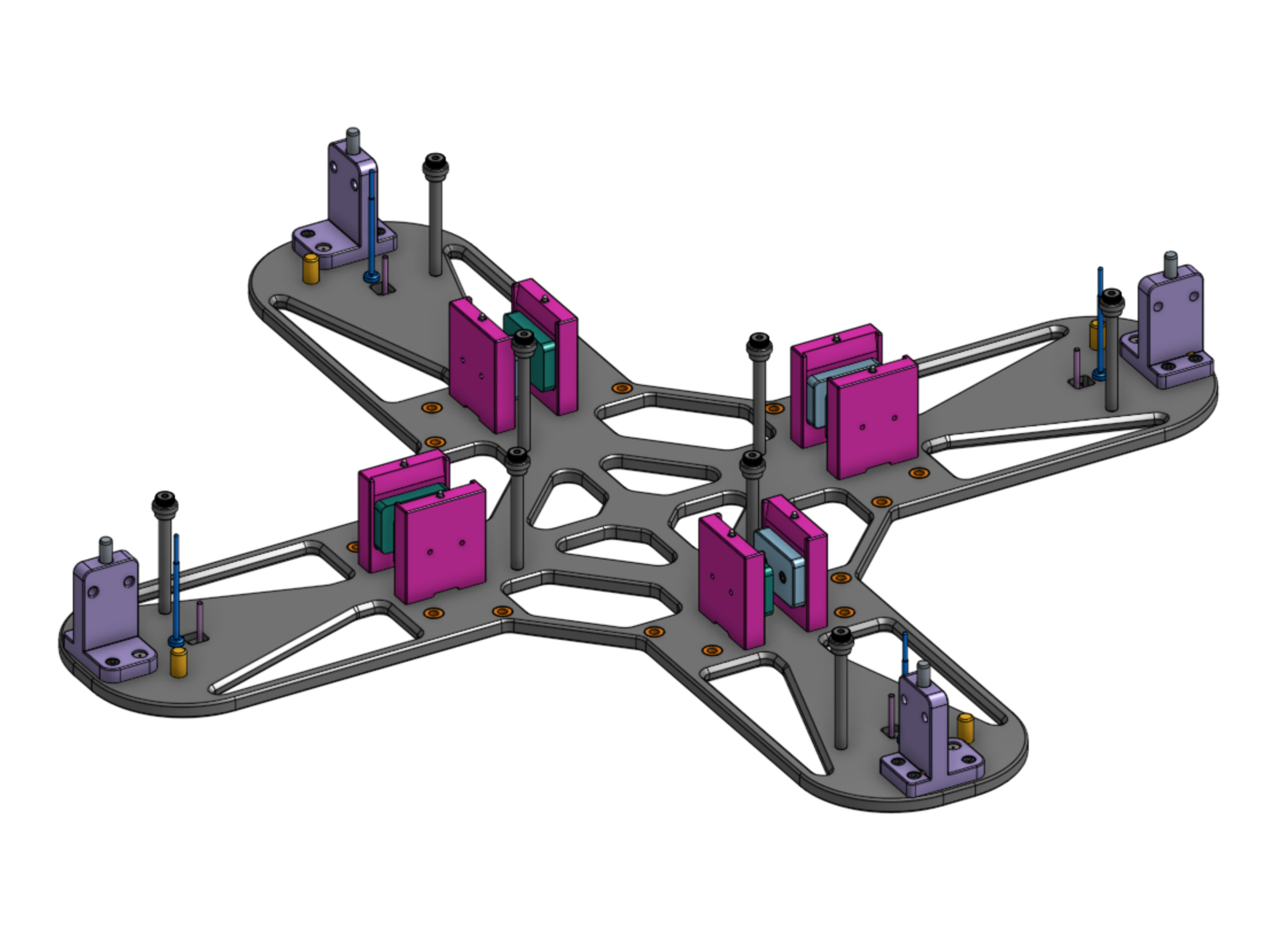

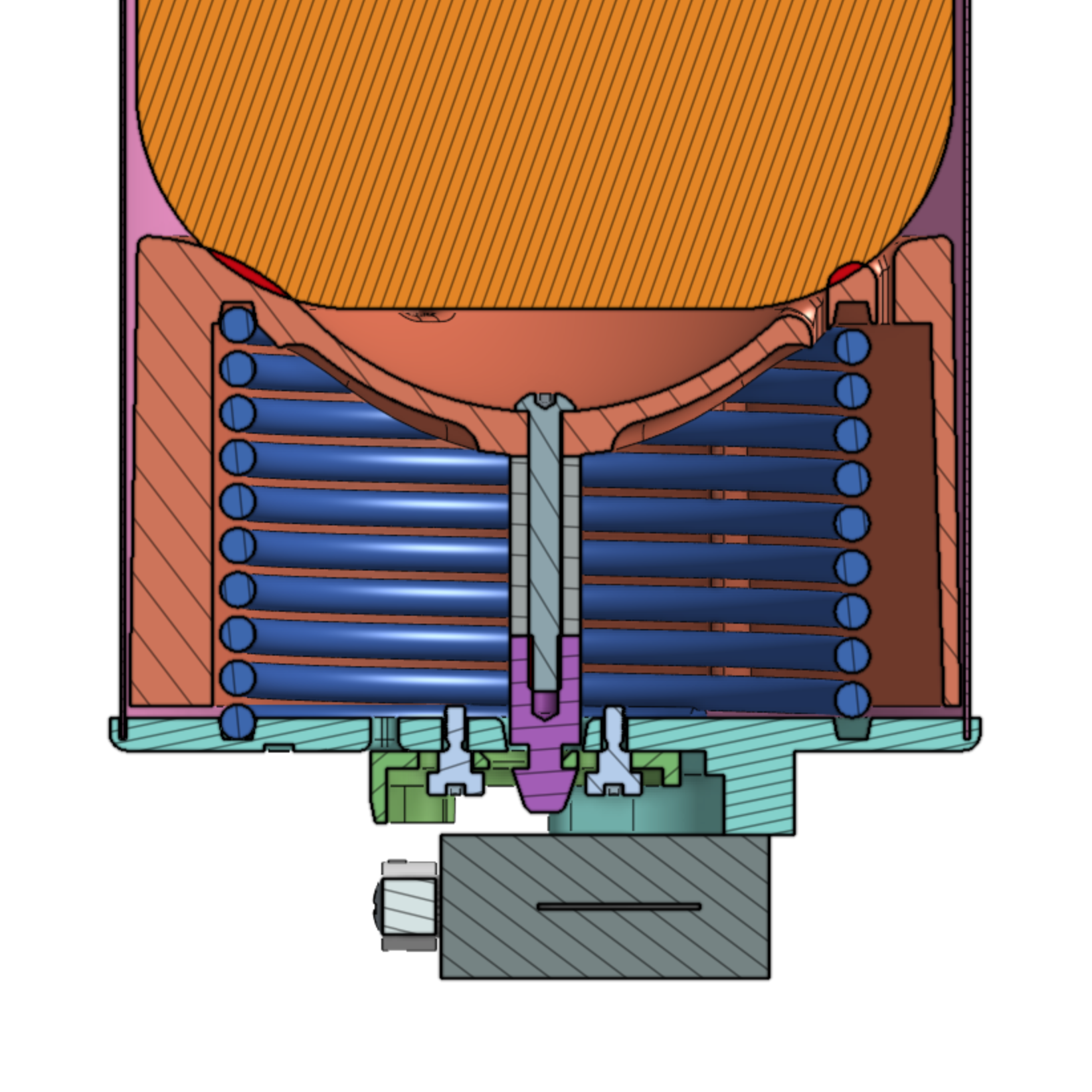

Redesigned airframe tooling for ramp-up and improved ergonomics. Tooling is approximately 1m x 1m. Three sets of the tooling entered production line Q4 2019 and have been used successfully through 2020.

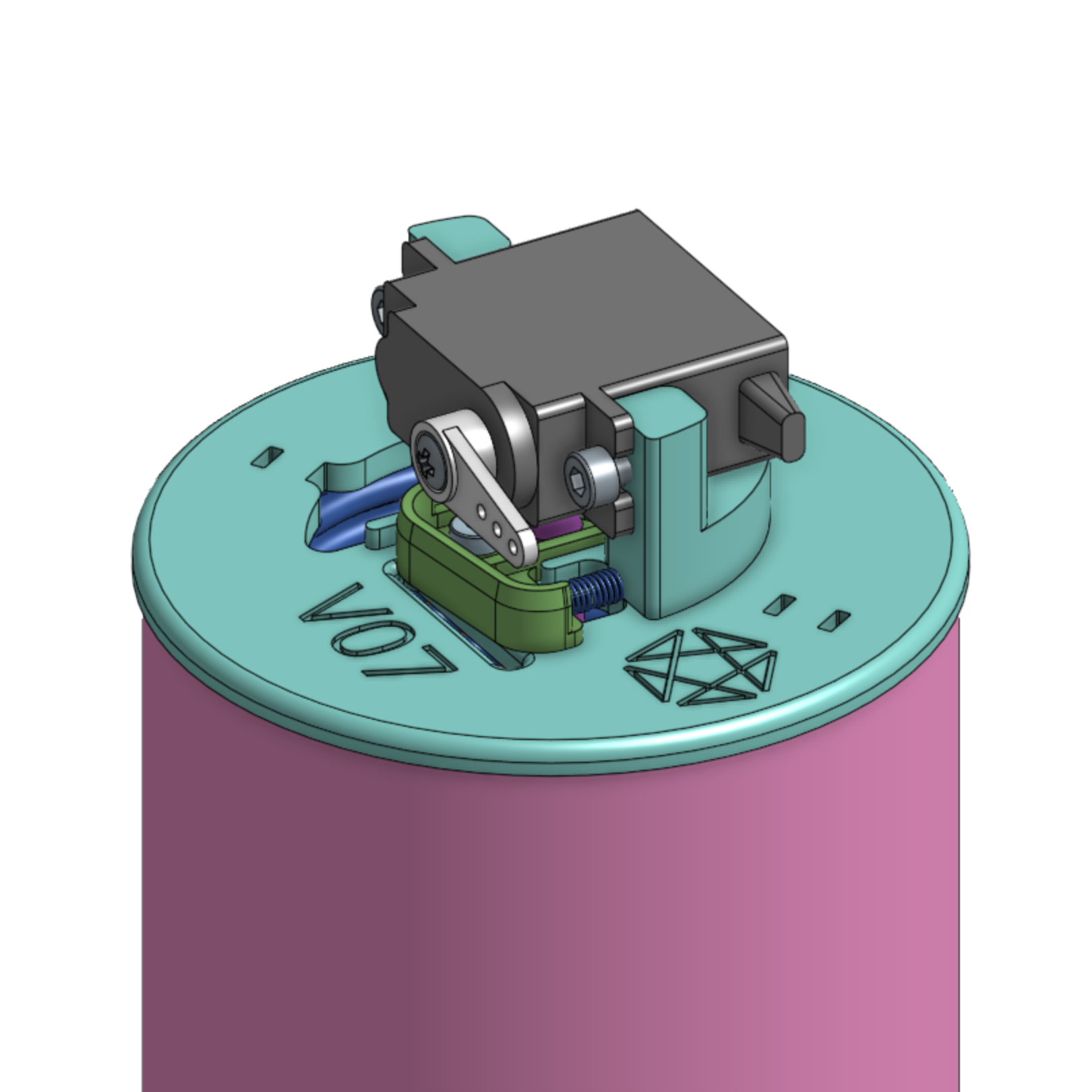

Completed initial design of servo-actuated parachute deployment device. Created functional 3D-printed prototype.

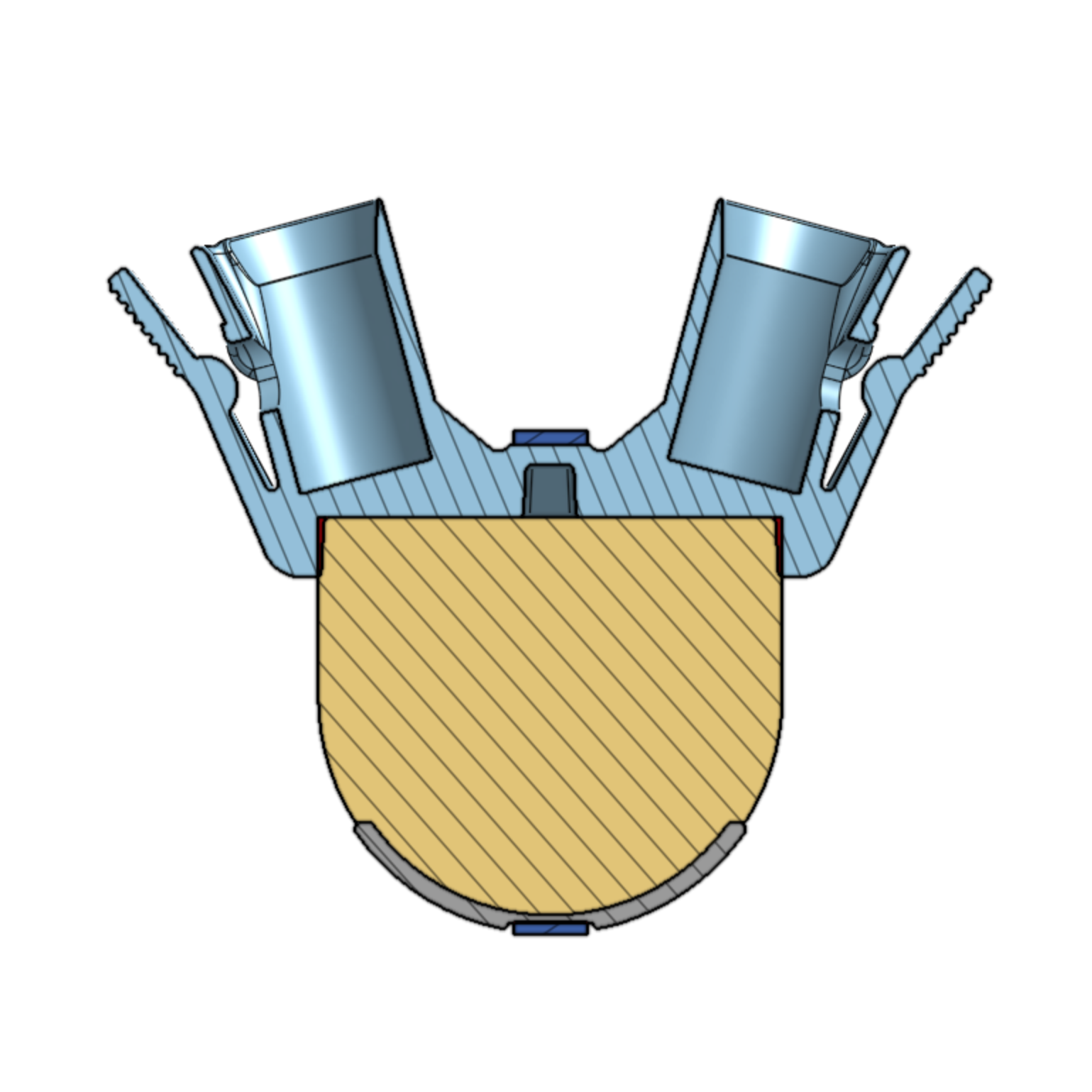

Designed improved detachable nylon landing feet with ergonomic release clips. Completed durability testing with a universal test machine and introduced to production line.

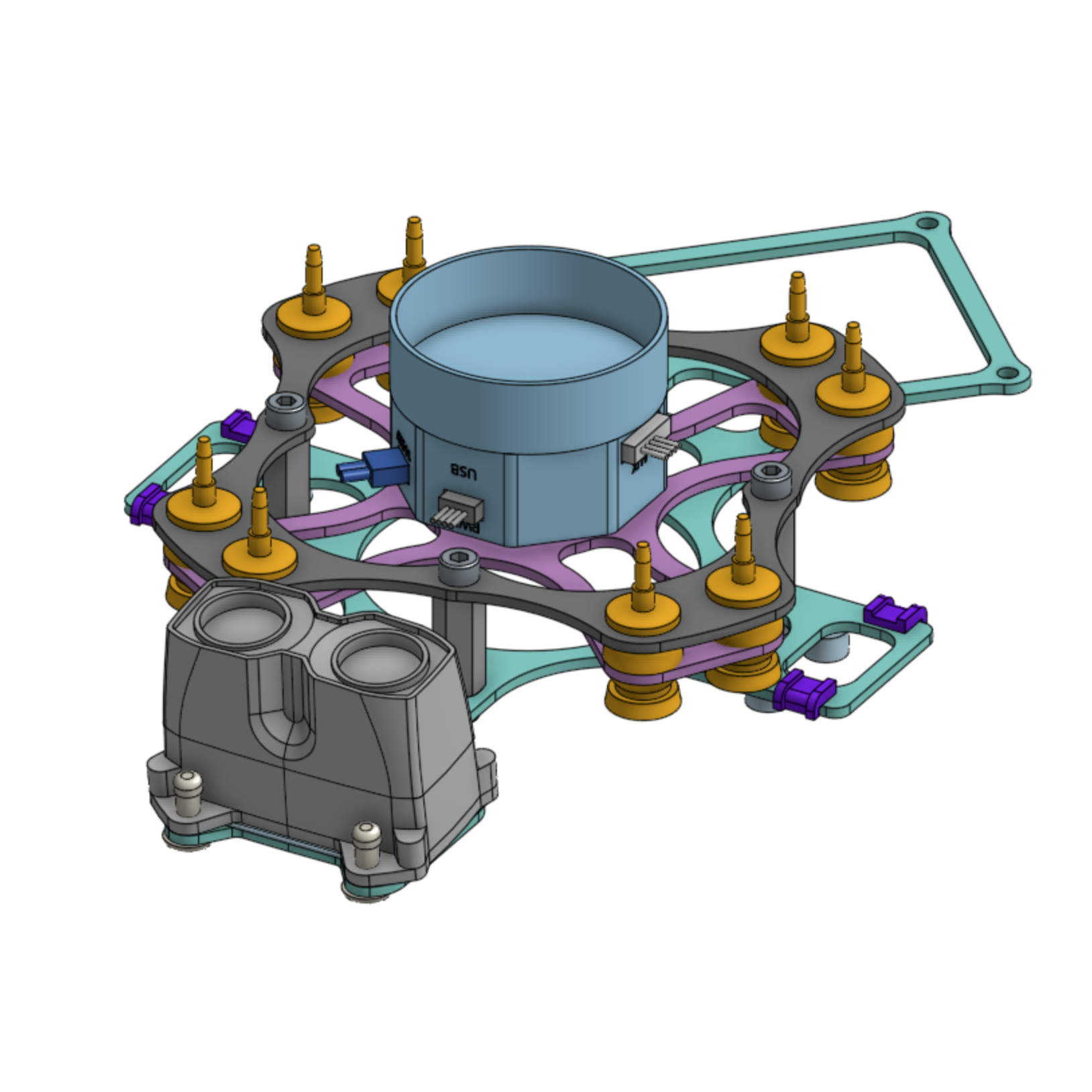

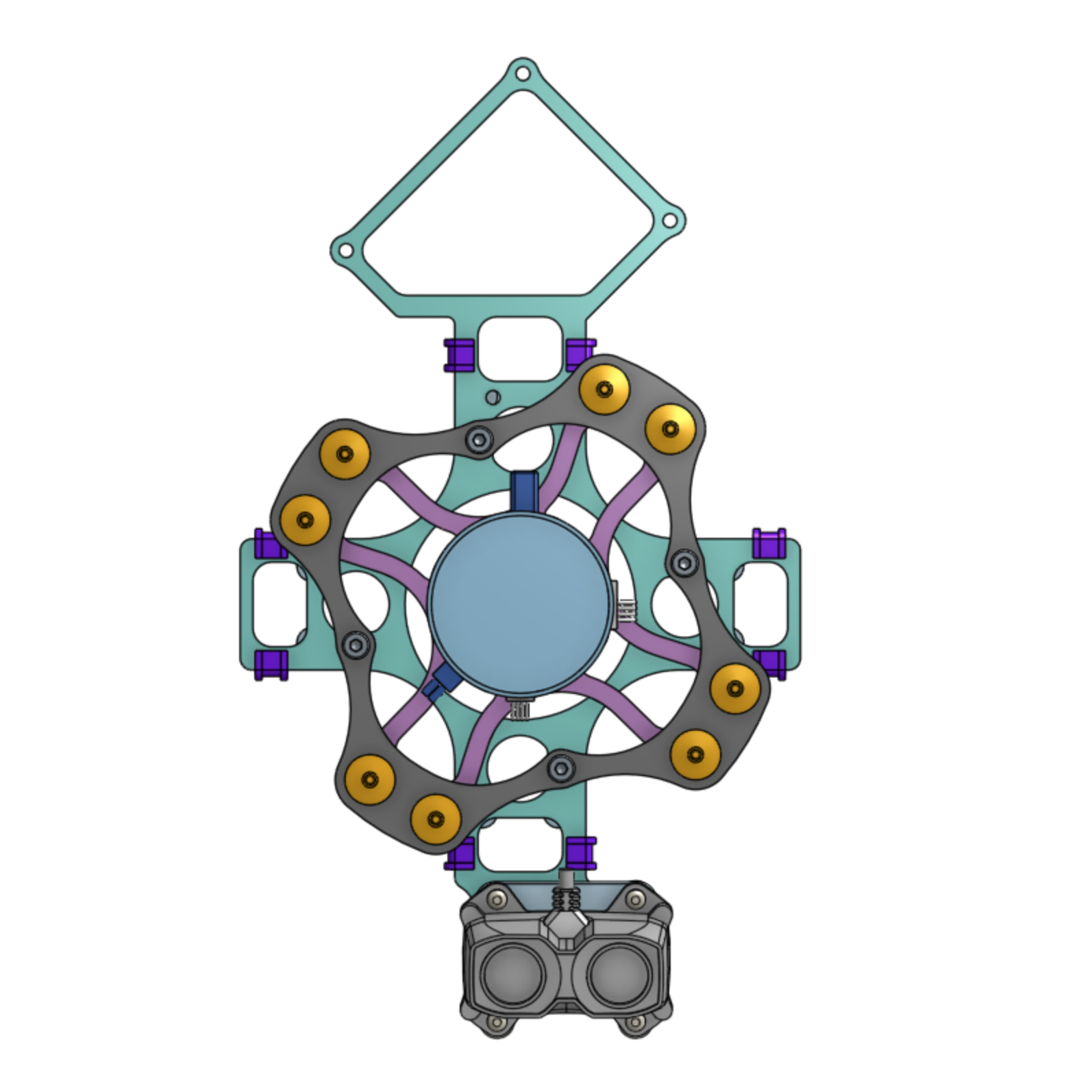

Designed lightweight vibration-isolated payload adapter for heavier camera.

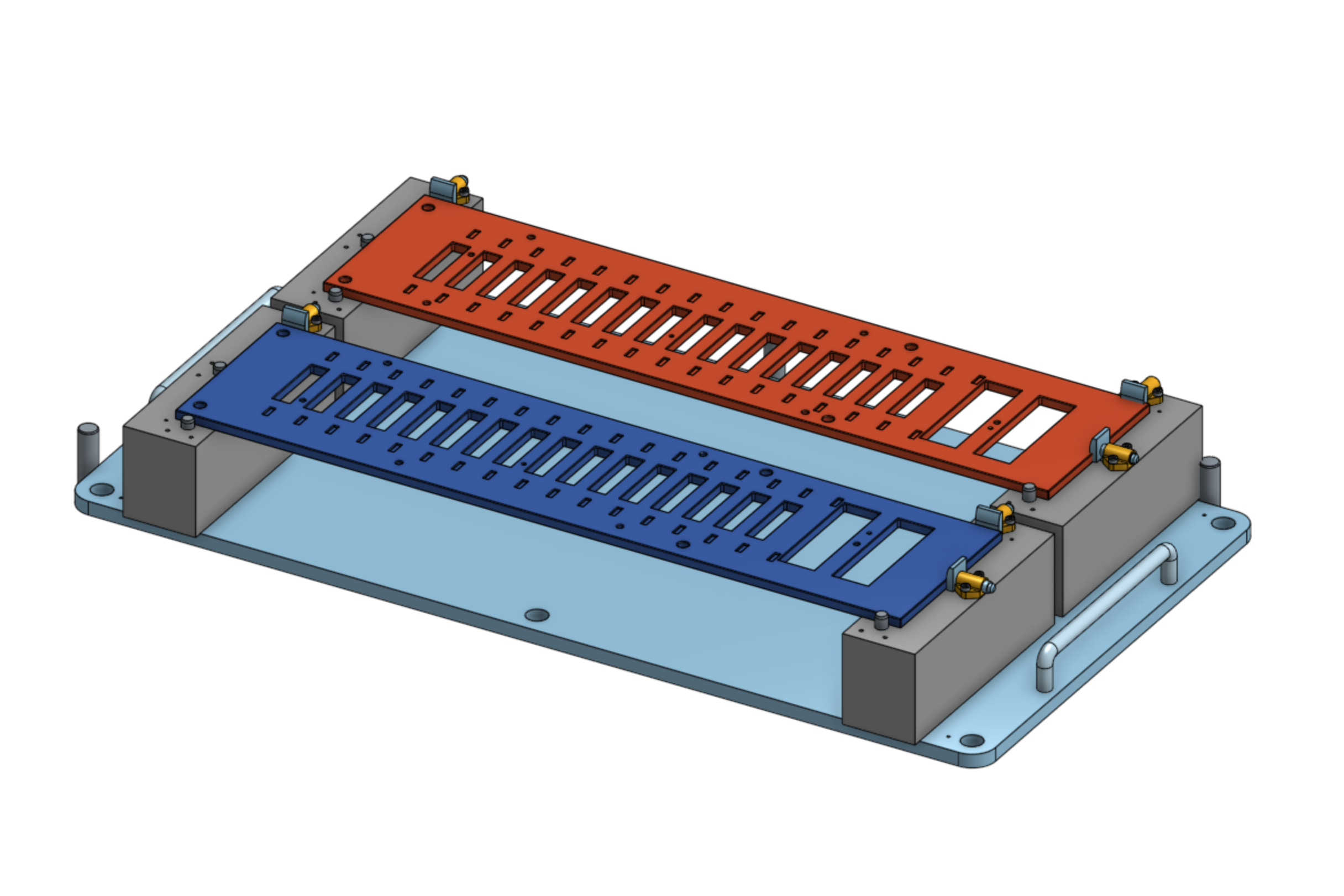

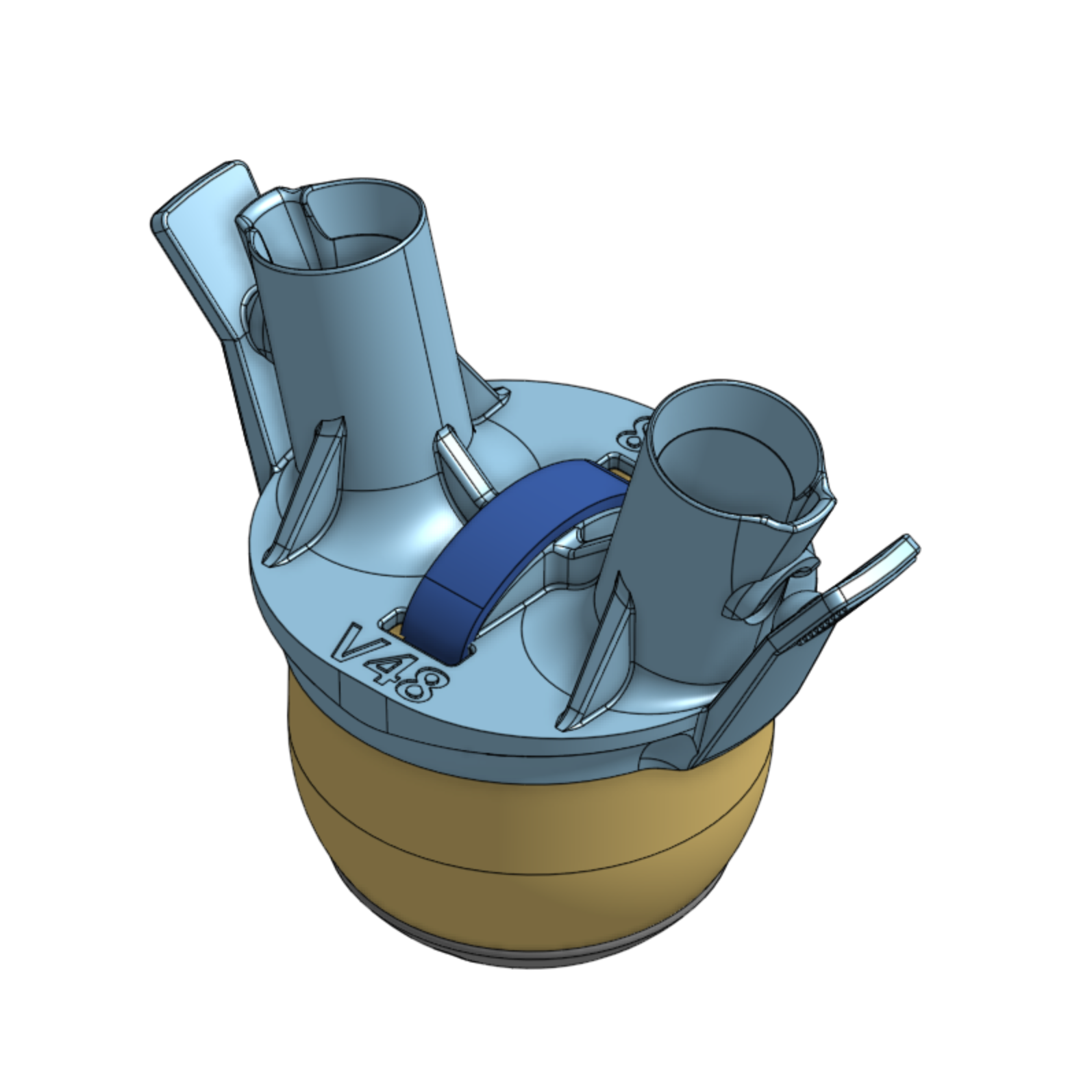

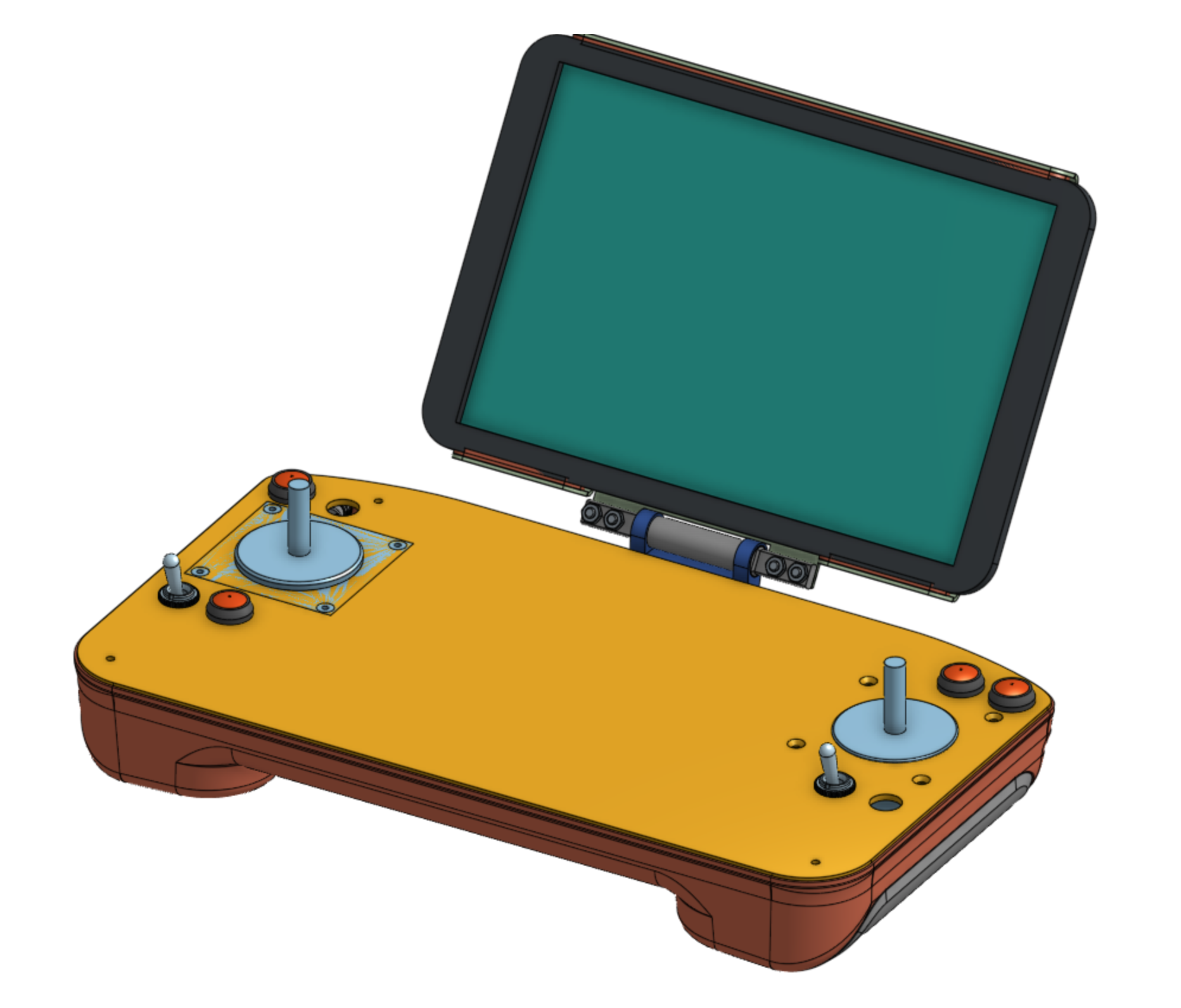

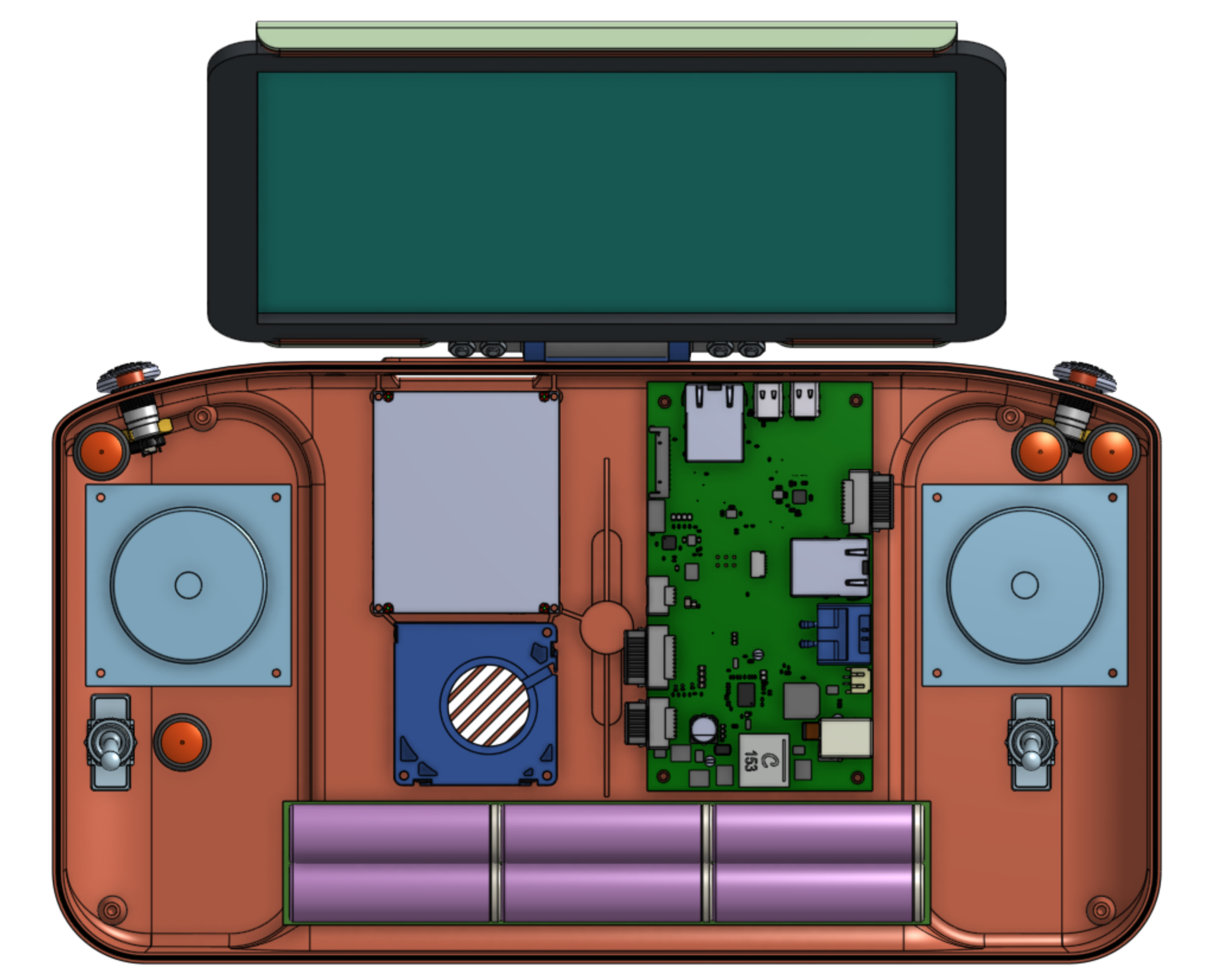

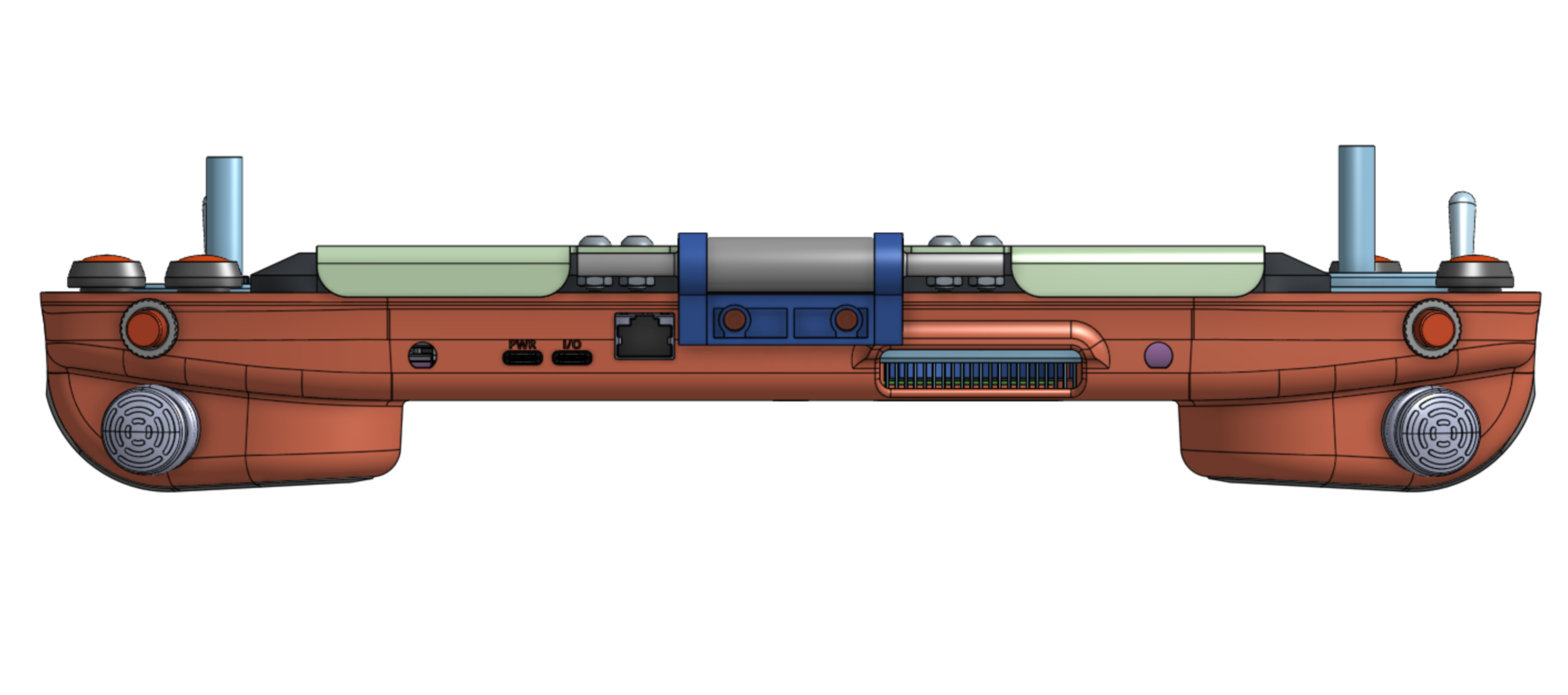

Designed ground station (handset). Completed first-pass injection molding DFM with vendor and assembled fit-and-feel prototype.