From my first day of high school to my last, I was on my schools FIRST Robotics Competition (FRC) team, helping to build 4 season robots and 4 off-season t-shirt launcher robots.

Every fall, we would create a robot to launch t-shirts into the crowd at the Thanksgiving pep rally using a pneumatic cannon, then each January, the 6 week "build season" would be kicked off with the release of the details of that years game, almost always involving manipulating some sort of ball or other sports equipment.

Each of these 6-week sprints was a microcosm of the typically longer engineering design process. In doing four of these, I learned a lot about project management and its general pitfalls, as well as gaining a lot of hands-on experience building prototypes.

In my last year on the team, the spring before graduating, I was team captain, and we used CAD extensively and had a few more sponsors than normal, and things went quite well.

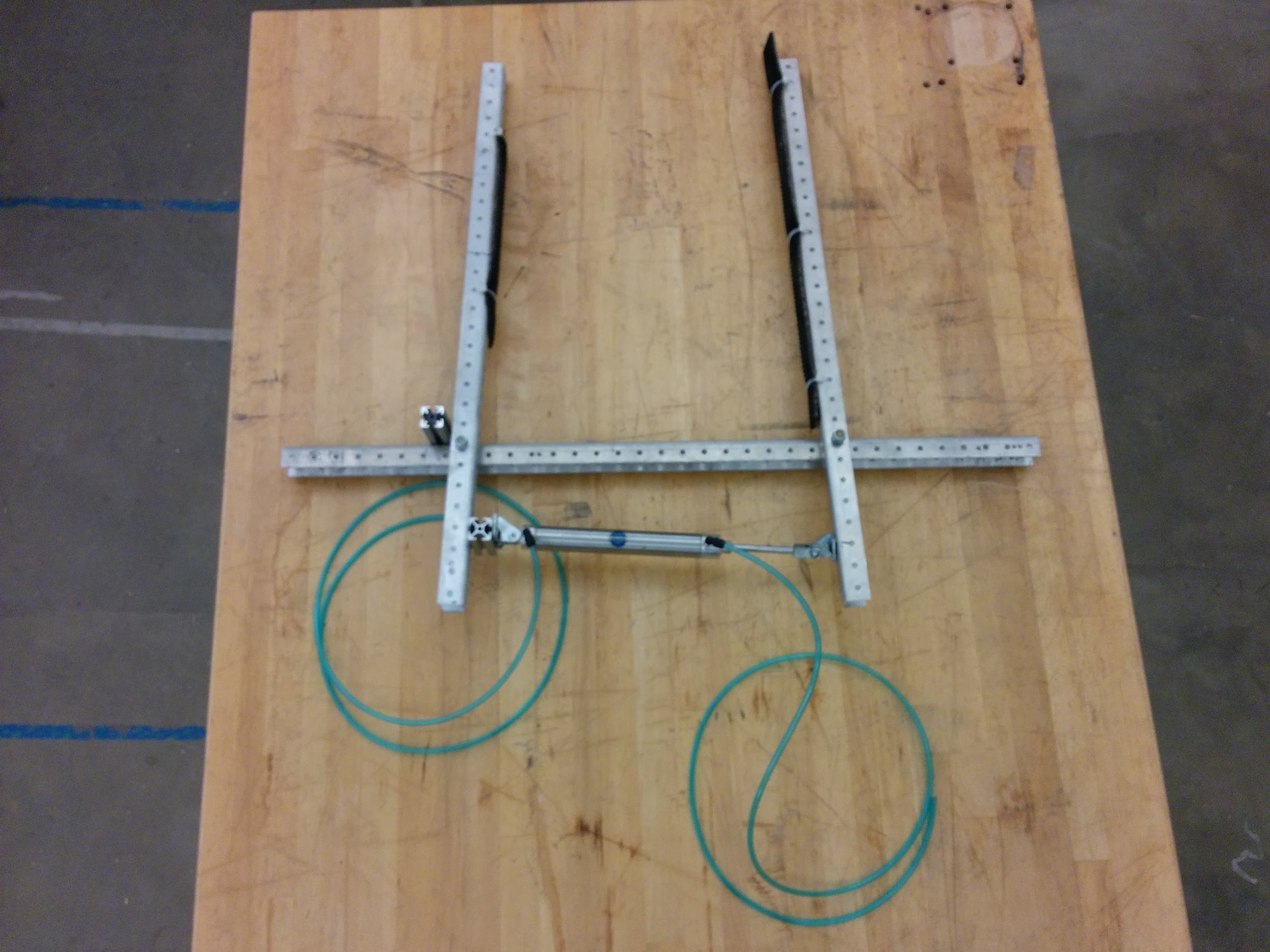

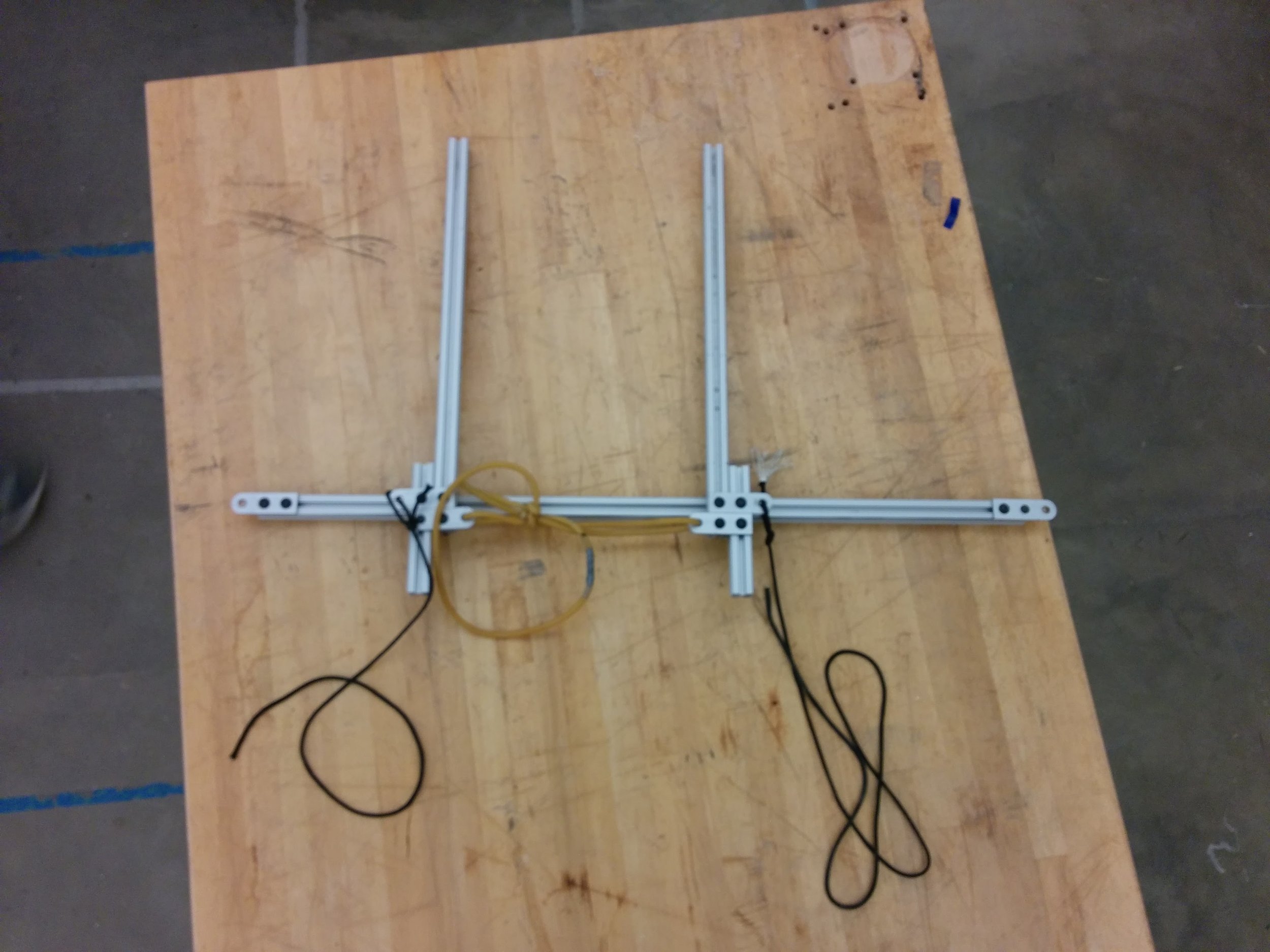

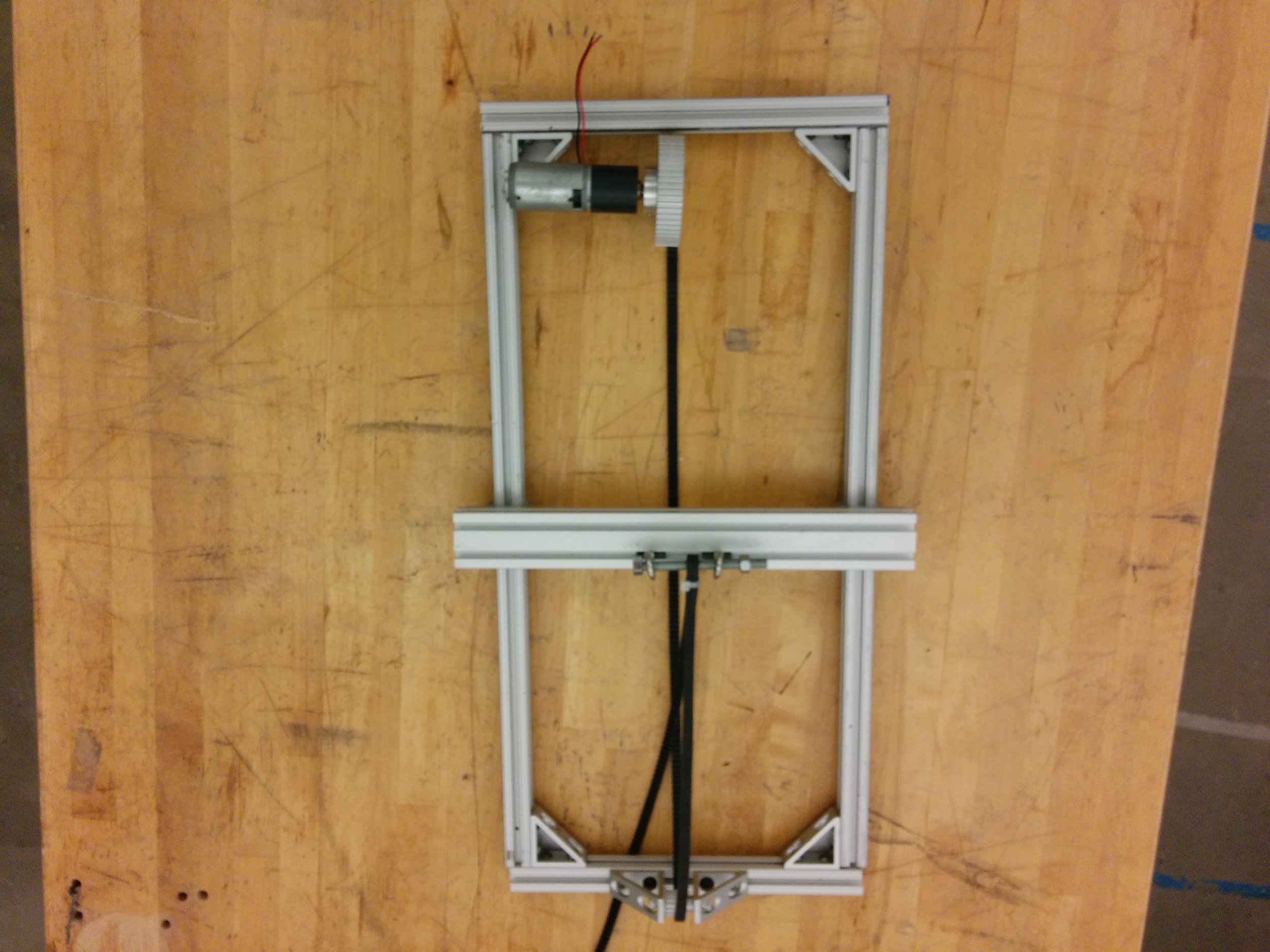

Below are two gripper prototypes and a belt-driven linear slide prototype, the last two of which were implemented in the final robot.

The elevator prototype, as controlled by a motor controller

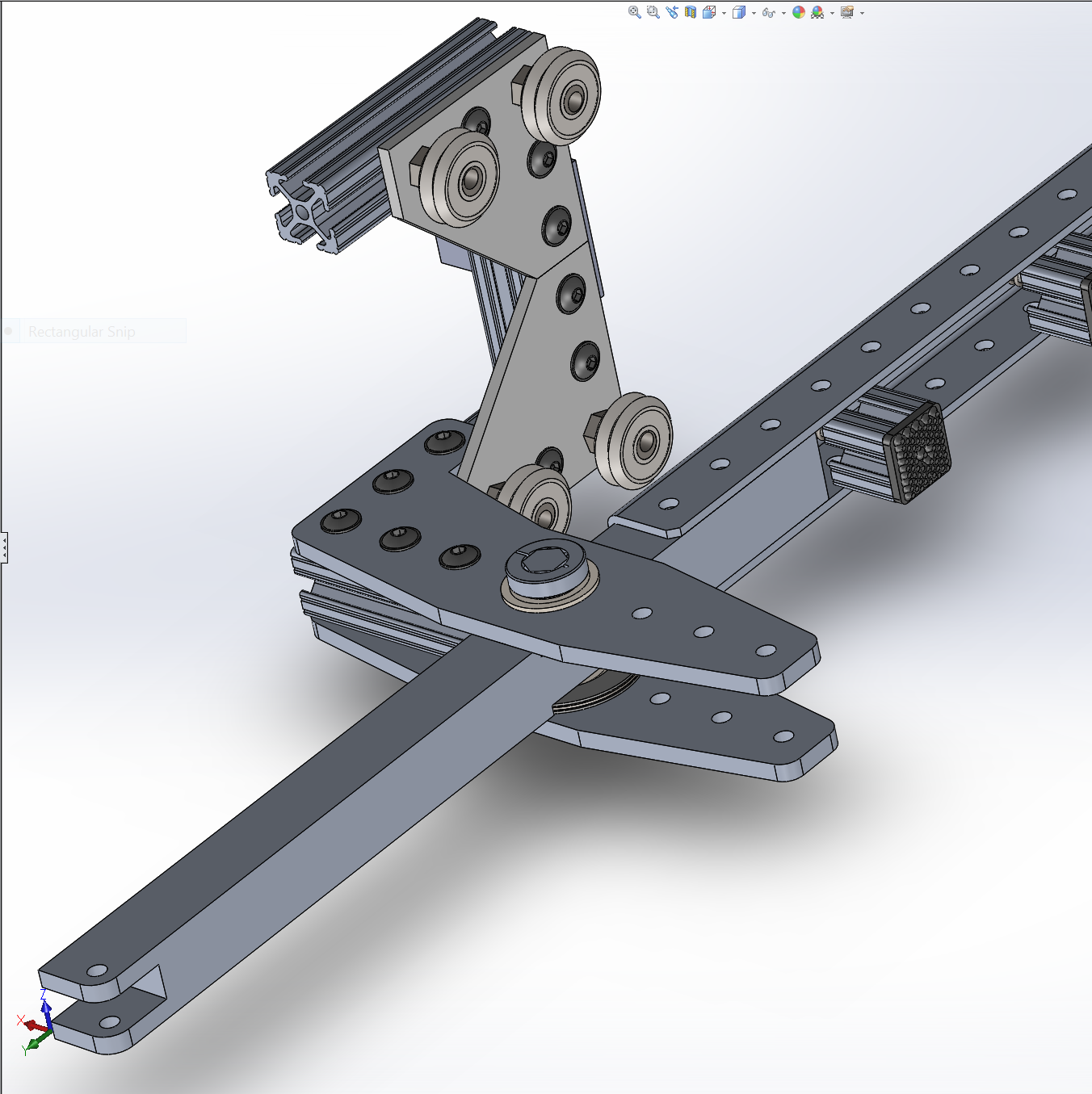

One of the sponsors we had this season was Massachusetts Machineworks, a local machine shop, which was utilized very effectively in precision-cutting the members of the custom frame which would later be riveted together, as well as some complex parts for the joints of the gripper, something that would not have been possible without such a resource.

The gripper design, pictured below was probably the most mechanically impressive part of the robot, it utilized cylindrical roller thrust bearings to handle the cantilevered load of 4+ plastic bins, weighing about 50 lbs in total without binding or jamming.

Below you can see the SolidWorks model of the entire robot, as well as a closeup of the gripper joint, the machined parts, some belt tensioners made out of novelty clothespin torsion springs, and the electrical design.

At the competition, we managed to stack 12 totes in 2 minutes!